date:2023/08/10

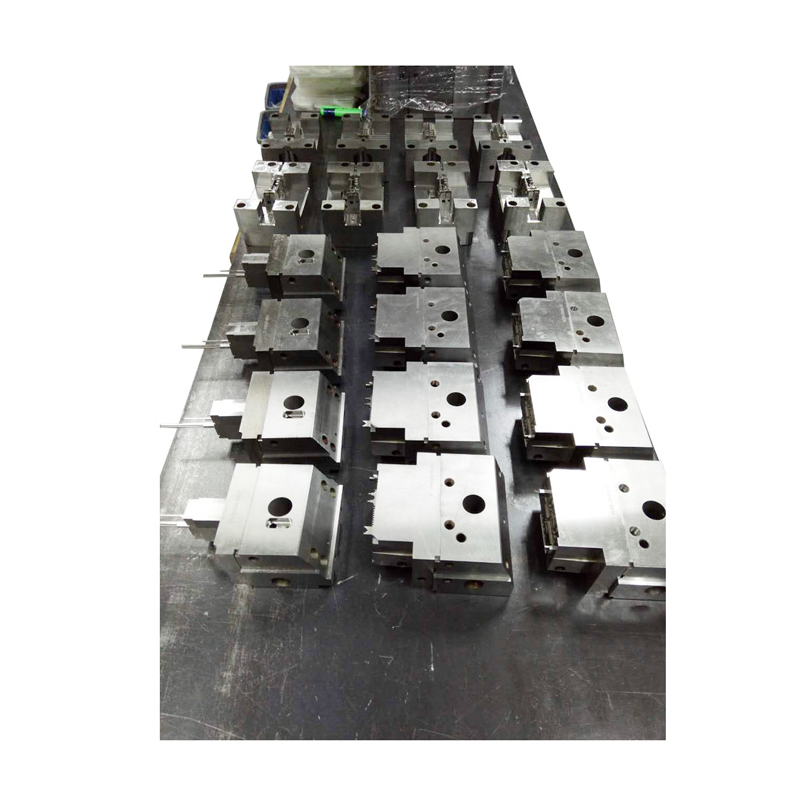

The plastic mold structure mainly includes a female mold with a variable cavity composed of a female mold combination substrate, a female mold component and a female mold combination card board, a male mold combination substrate, a male mold component, a male mold combination card board, and a cavity A punch with a variable core composed of a truncated assembly and a side-cut combination plate.

In order to improve the performance of plastics, it is necessary to add various auxiliary materials to the polymer, such as fillers, plasticizers, lubricants, stabilizers, colorants, etc., in order to become a plastic with good performance.

Plastic mould.

1. Synthetic resin is the most important component of plastic, and its content in plastic is generally 40% to 100%. Because of the large content, and the nature of the resin often determines the nature of the plastic, people often think of resin as a synonym for plastic. For example, mix polyvinyl chloride resin with polyvinyl chloride plastic, phenolic resin and phenolic plastic. In fact, resin and plastic are two different concepts. Resin is an unprocessed raw polymer, which is not only used to make plastics, but also as a raw material for coatings, adhesives and synthetic fibers. In addition to a very small part of plastic containing 100% resin, most plastics, in addition to the main component resin, also need to add other substances.

2. Filler filler is also called filler, which can improve the strength and heat resistance of plastics and reduce costs. For example, the addition of wood powder to phenolic resin can greatly reduce the cost, making phenolic plastic one of the cheap plastics, and at the same time can significantly improve the mechanical strength. Fillers can be divided into organic fillers and inorganic fillers, the former such as wood flour, rags, paper and various fabric fibers, etc., the latter such as glass fiber, diatomaceous earth, asbestos, carbon black and so on.

3. Plasticizers Plasticizers can increase the plasticity and flexibility of plastics, reduce brittleness, and make plastics easy to process. Plasticizers are generally miscible with resins, non-toxic, odorless, light- and heat-stable high-boiling organic compounds, and phthalates are commonly used. For example, in the production of PVC plastics, soft PVC plastics can be obtained if more plasticizers are added, and hard PVC plastics can be obtained if no or less plasticizers are added (amount <10%). .

4. Stabilizer In order to prevent the synthetic resin from being decomposed and destroyed by light and heat during processing and use, and to extend the service life, a stabilizer should be added to the plastic. Commonly used are stearate and epoxy resin.

5. Colorants Colorants can make plastics have various bright and beautiful colors. Commonly used organic dyes and inorganic pigments as colorants.

6. Lubricant The role of the lubricant is to prevent the plastic from sticking to the metal mold during molding, and at the same time make the plastic surface smooth and beautiful. Commonly used lubricants include stearic acid and its calcium and magnesium salts. In addition to the above additives, flame retardants, foaming agents, antistatic agents, etc. can also be added to the plastic.