date:2023/08/10

The actual classification of plastic molds

Many customers are not sure what type of plastic mold production and processing is suitable for their own products. The materials presented by the professional technicians of the injection mold manufacturers are shared below, so that everyone has a certain grasp of the plastic mold, which is more convenient. Communication is beneficial to its own product development. The classification of plastic molds is roughly divided into 8 categories:

1: beveled plastic mold production and processing beveled plastic molds are only suitable for angled plastic machines, which is very different from other plastic mold production and processing is that such abrasives are fed during forming The orientation of and the orientation of the opening and closing mold are vertical. His popular channel is established on both sides of the clinical diagnosis surface of moving and fixed molds, and its cross-section generally does not change, which is different from other plastic machine grinding, the top of the popular channel, in order to avoid plastic machine nozzles With the damage and deformation of the inlet end of the popular channel, the removable flow channel insert can be set.

2: The production and processing of plastic molds with the mold-out organization on the fixed mold In most plastic mold production and processing, the mold-out equipment is installed on the side of the moving mold. Work. In the specific production and manufacturing, because some plastic parts are limited by the appearance, leaving the plastic parts on the side of the fixed mold is stronger for forming. This makes the plastic parts slip off from the abrasive tool. Molding organization. Due to the limitation of appearance, leaving the plastic part on the side of the fixed mold is stronger for forming. This makes the plastic part slip off from the grinding tool, and the mold structure must be set on the side of the fixed mold.

3: Fully automatic production and processing of plastic molds with external threads. For plastic parts containing external threads, when automatic mold release is specified, a rotatable external thread core or ring can be set on the grinding tool, and the mold posture or The rotation organization of the plastic machine, or set a professional gear drive, push the external thread core or external thread ring to rotate, and then slip off the plastic parts.

4: Production and processing of plastic mold without flow channel No injection mold of the flow channel refers to the method of using thermal convection to carry out heat insulation and heating, to maintain the molten state of the plastic from the die of the plastic machine nozzle and the concave mold, and remove the mold There is no pouring system software condensate for plastic parts. The former is called the injection mold of the adiabatic runner system, and the latter is called the injection mold of the hot runner system.

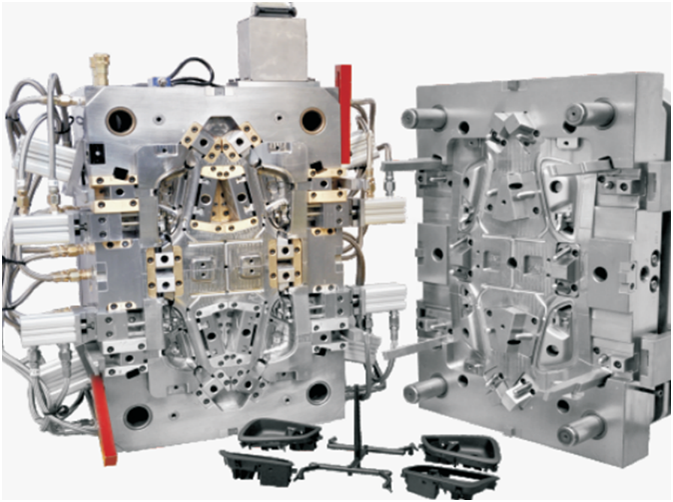

5: Production and processing of plastic molds with lateral clinical diagnosis and core-pulling tissues. When plastic injection processing mills have side holes or undercuts, it is necessary to select a core or rail slider that can be moved sideways. After the injection molding process, the moving mold first moves down a certain distance, and then the slope section fixed to the bending pin on the fixed template drives the guide rail slider to move outwards, and the swing rod of the mold organization promotes the push plate to make the plastic part Take off from the core.

6: The production and processing of plastic molds containing themed activity forming parts Because of some unique structures of plastic parts, Dongguan plastic mould processing manufacturers stipulate that the injection molds can be set to form thematic activity forming parts, such as the theme activity mold base, the theme activity cavity , Theme activity inserts, theme activity external threaded cores or rings, etc., can be removed together with the plastic parts when the mold is released, and then separated from the plastic parts.

7: When a single clinical diagnosis surface plastic mold is produced and processed, the moving mold and the fixed mold are separated, and then the plastic parts are removed, which is called a single clinical diagnosis surface abrasive tool, and is also called a double-plate mold. It is a very simple and basic method in plastic molds. It must be able to design a single concave mold injection mold or a multiple concave mold injection mold according to the design scheme. It is the most commonly used injection mold.

8: Production and processing of plastic molds with double clinical diagnosis surfaces. Injection molds with double clinical diagnosis surfaces have two clinical diagnosis surfaces. Compared with plastic molds with single clinical diagnosis surfaces, the plastic molds with double clinical diagnosis surfaces improve a part of the fixed mold that can be partially moved. The middle plate (also called the theme activity glue inlet plate, on which the glue inlet, the flow channel and other parts and components necessary for the fixed mold) are established, so it is also called the three-plate type (moving template, positive middle plate, fixed Stencil) plastic mold, which is commonly used in single concave mold or multi concave mold plastic molds that are fed into the glue inlet. When the mold is ejected, the positive intermediate plate is separated from the fixed mold plate at a fixed distance on the positioning pin of the fixed mold, which is convenient Remove the pouring material of the pouring system software between the two templates here. The dual-clinical diagnosis surface injection mold is cumbersome, the manufacturing cost is high, and the parts are difficult to process. Generally, it is not necessary to form large and medium-sized or giant plastic products.