date:2023/08/10

Mould is an effective tool for mass production of industrial products, which determines the product quality, efficiency and new product development capabilities. Therefore, the level of mold production technology is an important indicator of the level of a country's equipment manufacturing industry, and it is also compared to the "aircraft carrier" of industrial production. In my country, 75% of rough-processed industrial product parts and 50% of precision-processed parts are formed by molds, and most plastic products are also formed by molds. In the past 10 years, my country's mold industry has been developing rapidly at an annual growth rate of 15%.

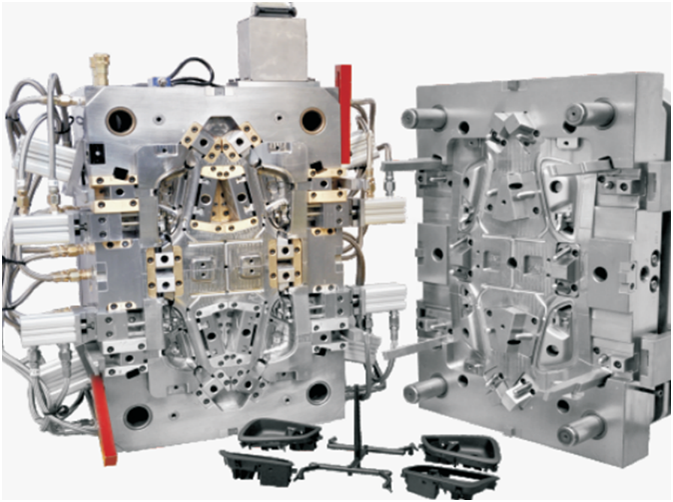

Dongguan precision plastic mold

I believe that many people have seen many cases of mold factory automation in the Western world, but why foreigners who are not far away come to China and other countries with relatively abundant human resources and relatively low labor quality to send mold orders? Why do they not In the industry 4.0 method, use automated unmanned factories to make molds? This shows that not all molds can be made by automated methods.

This seems to be a bit pessimistic for the application of mold automation. What is certain is that for certain products with high similarity, or a certain product requires batch molds, then the manufacturing of these molds can achieve a high degree of automated manufacturing to enhance the competitiveness of mold factories.

For single-set mold manufacturing and ever-changing mold manufacturing, there are still some problems to apply mold automation to production!

Now the automation boom in the mold industry is unstoppable. From a development perspective, this is of course a good thing. The mold industry does need to eliminate some backward manual models. However, if the matter of automation is used in the mold industry, don't simply think that as long as you spend money to invest in the most advanced automation technology, you can replace the technicians to make high-quality molds. This is a big misunderstanding. The mold managers and seniors of the company can be distinguished, and the most feared investment is a bunch of unworkable decorations!

There are many problems in mold workshops that are mainly slow, ranging from slow finding things to slow processing to slow logistics, and this cannot be solved by automation. Automation means that after humans transfer the limited digitization of the knowledge system in the human brain to the computer, they are just very rigid and perform a series of actions without perception. Of course, they do not know the meaning and purpose of these actions. Automation at this stage is in fact dull.

We all feel that there are no craftsmen in the workshop, so we can't make molds well. Similarly, we can't expect robots without perception to make molds. Do they know what is called?

Just like PM software can't program good toolpaths by itself, UG software can't draw good graphics by itself, it still needs high-quality designers and programmers to use the software well.

Then we need to have a high-quality team to solve all the problems on the production site with people first, and after satisfying the customers, then quantify the satisfactory results with data to form instructions that can be executed by the automation equipment, and let the automation equipment execute the instructions Only when the result of the action is closest to the result of manual operation can the function of the automation equipment be achieved.

When a team can't rely on the knowledge system and practical ability of the human brain to achieve customer satisfaction, let alone use automated equipment to achieve customer satisfaction?

A mold factory that can operate normally must start from the 5M1E man-machine material method test ring, step by step to improve all aspects of the problem, including water, electricity, fluid, tooling, logistics, design, process, plant planning, supply chain optimization It’s not too late to talk about automation after the human brain solves this series of problems, such as information management.

After looking at the site of many mold manufacturing factories, I think that the profitability of molds depends on two guarantees: the best design scheme and the best processing efficiency.

There is no inevitable relationship between high-efficiency processing and automation of typical single-piece flow workpieces such as molds. The core of automation is numerical control, and the core of numerical control is programming. The programming mentioned here includes the meaning of data generation and control of the whole process. It is precisely the quantification of high-complexity three-dimensional objects such as the mold, and the huge quantified data stream, according to the process sequence and quality requirements of mold processing, one-to-one correspondence with the physical object of the workpiece, and the human brain is satisfied with the judgment. The effect is absolutely impossible at this stage.