date:2023/08/10

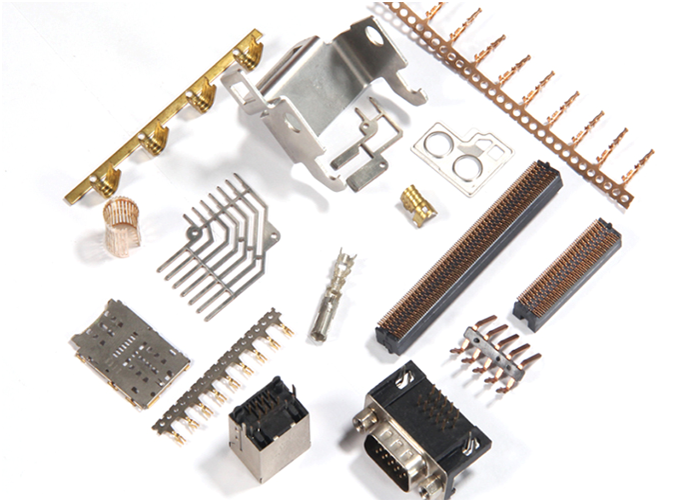

Metal stamping is a process that uses punches and molds to deform or break iron, aluminum, copper and other plates and other materials to achieve a certain shape and size. Metal stamping parts are now widely used in various fields of our lives, including some electronic devices, auto parts, decorative materials, etc. Let's take a look at how to prevent damage to metal stamping parts.

The following is how to prevent damage:

1. The sliding hinge shall not be made of aluminum alloy, but shall be made of stainless steel.

2. For sliding windows with a width of more than 1 meter, or double-glazed doors and windows, double pulleys should be installed, or movable elastic pulleys should be used.

3. Hardware fittings should be installed afterwards, door and window locks, handles, etc. should be assembled after the window and door leaves are inserted into the frame to ensure accurate position and flexible opening and closing.

4. To install hardware with fastening screws, a metal liner must be installed inside, and the thickness of the liner should be at least twice the pitch of the fasteners. It must not be fastened to plastic profiles, and non-metallic linings must not be used.

5. The models, specifications and functions of hardware fittings should conform to the current national standards and relevant regulations, and match the selection of plastic steel doors and windows.

6. Pay attention to maintenance after installation to prevent rust and corrosion. In daily use, lightly close and open lightly to prevent hard closing and hard opening, which may cause damage.